|

The first thing you have to look at in any kind of construction is the site. Orienting the home to take maximum advantage of passive solar design is of prime importance. It may also be possible to use the contours of the site to help design the home. For example, if there is a high spot on the site, it may be possible to build part of the structure into it to take advantage of earth sheltering, or to construct a lower level or basement. There may be other things on the site, which can help you - and some you may want to avoid. For example, the earth and rocks on the site may be material you can use for building, but there may be low areas on the site, which should be avoided due to flooding. Some of these decisions are value judgments, which require time and contemplation to evaluate. If a spot feels good and meets practical requirements, it's more than likely the best place. Many additional ideas on "Siting A Natural Building" can be found in a book titled "The Art Of Natural Building".

Building Codes are intended to protect the health and safety of people occupying a structure or those possibly affected by it or living near it. There is nothing wrong with Building Codes per se, but they are sometimes used to unnecessarily prohibit perfectly safe procedures or to limit alternatives. In some cases this is intentional, for example to limit construction procedures and materials to those championed by special interest groups. But sometimes there is just not enough good information available to allow Building Safety personnel to deviate from the book. This is where diplomacy and knowledge come in handy. Usually showing respect, knowing precisely what you want to do, and having good plans to accomplish it go a long way toward establishing rapport with Building Safety personnel. Usually your plans or procedure gain a lot of credibility if you can find a structural engineer or architect who is willing to approve (stamp) them. This approval stamp often costs quite a bit of money, but some practitioners have found progressive architects who are interested in working with innovative materials and charge very little.

Building Safety personnel have reason to be cautious. They don't want to be held responsible for approving a product or procedure which turns out to be unreliable or even dangerous. In many cases, it is possible to work with them. I have had very good experiences with those who have time and are willing to listen. I'm not sure that any of the following construction methods are approved in the Universal Building Code, but they have been used in structures which have been standing for years.

The function of a foundation is to support the load of the walls and roof of a structure, prevent settling, and provide a solid anchor point to hold the structure together. The foundation has to extend to a depth just below the frost line in your area. Basing the foundation below the frost line concentrates the load of your structure where it is much less subject to heaving. Heaving is movement caused by the expansion and contraction of moisture changed to ice during the freeze - thaw cycle. The foundation is usually comprised of a footing and stem wall. The stem wall is placed on the footing or is poured as part of the footing. The function of the stem wall is to elevate wall construction materials - in this case papercrete - above the ground. This serves to isolate them from moisture and provide a barrier against bugs and pests.

There are a number of ways to build footings and stem walls. One of the most common ways is to pour a concrete footing and stem wall in a single monolithic unit. This involves excavating a footing, placing steel rebar horizontally and vertically, and building forms to support the stem wall. There are variations on this approach, but they all cost quite a bit of money, and use a significant amount of concrete - in fact, the footing and stem can cost more than the rest of the papercrete structure combined. Concrete is strong and quite reliable, but has the propensity to "wick" moisture. If there is water in the surrounding soil, concrete will absorb the water through capillary action and pool it on its surfaces, including where the papercrete walls meet the stem wall. Since papercrete is very hydrophilic- absorbs water quite readily - this situation has to be stringently avoided. Ideally, the concrete footing and stem wall are isolated from the surrounding soil with drainpipes and/or a layer of gravel to drain water away. Additionally, some kind of barrier has to be placed between the concrete and the papercrete - either a good liquid sealer or a physical barrier like a polyethylene sill sealer.

|

Tires are stacked offset like bricks.

Drawing courtesy of “Building With Earth” by Paulina Wojciechowska. |

There are other ways to build footings and stem walls with tires or with rubble and sand bags. These methods are not formally recognized, but people are using them. The foundation with tires involves digging a tire-width trench, filling tires with gravel or earth, laying them horizontally in the trench, filling the tire openings with gravel or earth, tamping them and then constructing a stem wall on top of them.

This general approach is used in earth ship (rubber tire) construction for the foundation as well as the walls. Digging wide trenches and filling tires with earth is very labor intensive, but it works quite well.

|

Rubble footing with sand bag stem.

Drawing courtesy of “Building With Earth” by Paulina Wojciechowska. | The easiest and least expensive way that I've heard of is to build a solid foundation for papercrete walls is with rubble and sand bags. It is not code, but variations of it have been used successfully to support many structures. A trench several inches wider than the wall is dug to just below the frost line. Thoroughly tamp the bottom of the trench. Starting at the bottom, layers of progressively smaller stones are placed on top of one another. The bottom layer should be the coarsest, perhaps 4 inch (10 centimeter) stone, followed by a layer of 2 inch (5 centimeter) stone, followed by one-inch (25mm) stone and ending with pea gravel several inches above grade. Screening your own gravel is a lot of work, and it is not often possible to get uniform selected sizes commercially. Usually the sand and gravel yards sell ranges of sizes like 1/2" - 3/4", 3/4" - 1 1/2", 1 1/2" - 3", 3" - 8", 6"+, etc. (1.3 - 1.4, 1.4- 4.0, 4.0 - 8.0, 8.0 - 20.0, 15.0+ centimeters)

If you can pick up what you need yourself, the prices average about $6.00 a ton. If delivered, figure $15.00 a ton plus a truck rental charge. The thickness of each layer and number of layers depends on the depth of the trench. As each layer is added, it is tamped and leveled with a tamper or a 2 x 4 until the last layer is a few inches above grade. Then two layers of sand bags are laid on top of the rubble foundation. The sand bags become the stem wall. Make sure that sand or small gauge gravel is used to fill the bags. If earth is used, and there is a significant amount of silt or clay in it, there is a good chance the bags will wick water more readily than concrete. Also be sure that the same amount of sand is placed in all bags. If the amount of sand varies significantly, the size and thickness of the bag will vary making it difficult to keep the stem wall level and uniform in thickness.

|

| An 8-inch piece of stovepipe holds the bag open and measures the amount of sand. | This is a problem especially when more than one person is filling bags. I found a way to keep the amount of sand constant and hold the bag open as well. I bought an 8-inch (20 centimeter) diameter piece of stovepipe and placed it in the bag. When filled, this stovepipe piece held a little too much sand so I cut off a section until it held just enough sand for the type of bag I was using. Incidentally, there is a tendency to overfill bags. If overfilled, the bag will belly out and become overly round - even after tamping. This makes layers of bags unstable. It's best to look at the creases of the bag and tamp a few bags to determine how thick the bag should be filled. The idea is to get the most flat solid area after tamping. After finding out how much sand it takes to do that, pour the sand from that bag into the stovepipe, mark it and cut if off so that only that amount can be added. The stovepipes are cheap - five or six dollars. It's easy and inexpensive to make these "measuring cups" so that everyone filling bags has one.

Layers of bags are laid with offset joints like brick. Two strands of barbed wire are placed in parallel along the length of - and between the layers of - the sand bags to keep them from sliding across one another. To keep the papercrete wall from shifting on the sand bags, 3/8 inch (1.8 centimeters) rebar is pounded through the sand bags, at two to four feet intervals, as deep into the rubble footing as they will go. Pounding rebar through the rubble footing may be difficult, but I'm told that the rebar sometimes finds its way between the stones. Most people start rebar with a post driver.

|

| A post driver is used to start the rebar. A mall is used after the rebar is far enough in to be stable. | They cost about $20.00 at Home Depot. It’s a lot easier on the hands than using a mall. The post driver leaves a few inches protruding, so a hand mall has to be used to pound the remaining length of the rebar all the way in. But at that point, the rebar is stable enough to save hitting your knuckles with the mall. If the rebar will not penetrate the footing at a given point, try pounding it in at a different angle. If the rebar won't go into the foundation at all, just leave it impaled in the bags. The idea is to stabilize the first few courses of papercrete on the sand bags, not nail the bags to the footing. The weight of the bags and the papercrete will keep the walls from moving on the footing.

Actually, at least one home I visited had no footing at all. The site where the home was to be built was very sandy and had no problem with drainage. The seasonal temperature changes were not extreme enough to cause heaving in loose, sandy soil. So the builder simply leveled an area for the home, and then spread out about six inches of scoria, a porous volcanic rock, for sub-floor drainage and insulation. Next he laid a few courses of sand bags right on top of the scoria. He finished the entire building, walls and roof, with bags of scoria covered with papercrete. So, absent problems with drainage and frost heave, if walls are thick (i.e. building loads are spread over a wide base), footings may not be necessary. Many ancient buildings, standing for hundreds of years, are built on the ground without footings.

|

| Some of the walls at Chaco Canyon are three stories high, built on the ground, have little or no mortar and have been standing for hundreds of years. | In fact, un-reinforced rubble and shaped stone have been used for foundations and walls for centuries before Portland cement and rebar were discovered. Some of the early Native American stone structures of the Southwest, like those at Chaco Canyon and Pueblo Bonito, are centuries old, several stories tall and still intact. Some have mud mortar and others have no mortar at all. Larger stones were chinked so skillfully with smaller stones that nothing else was needed.

Tamping together layers of progressively smaller stones promotes drainage and strength. Wedging smaller stones between larger stones would seem to stabilize the layers and distribute the load in a horizontal as well as vertical plane. Unlike a concrete footing and stem wall, a rubble footing with sand bag stem wall will theoretically not wick water at all.

“Building With Earth” ,by Paulina Wojciechowska, has a detailed section on foundations. We plan further experimentation with these foundations early next year.

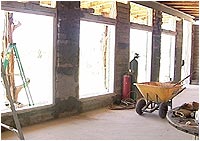

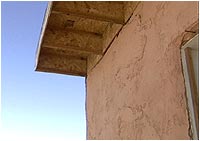

Ironically, the first decision about walls starts with the roof. Will the papercrete walls support the roof or will the roof be supported some other way? Currently, it is difficult to get a permit to build a home with papercrete if it is “load bearing," that is if the roof is supported by the walls. Not enough testing has been done. It is easier to get approval to build roof-supporting garages, sheds or other structures, since they are not intended to house people. Many localities will permit papercrete walls as “in-fill “ for homes - that is as non-load bearing walls built between roof-supporting posts. The posts are connected to the foundation at the bottom and tied in to beams on top. The roof system is built on top of the beams. This approach is commonly called “post and beam."

|

| A post and beam home with papercrete walls used as in-fill. | The posts and beams may be made of wood or steel or a combination of both – depending on local building codes. I know of one home built with steel post and beam materials, which the owner was able to obtain nearly for free, because he was an expert welder. If you want to build inexpensively, you will become familiar with your local demolition and junk yards. It’s often possible to obtain excellent deals on building materials in these places, while at the same time be recycling valuable resources. If the building authorities in your area go entirely by the book, be careful to check with them regarding what recycled materials are permissible.

No matter which method you choose to support your roof, the walls are built the same way. The rebar, as described above, has ideally been pounded into the rubble foundation, and has been allowed to protrude a few feet above the sand bags.

|

| Rebar protruding above a concrete footing. | The first three or four courses of papercrete will have to be drilled or impaled on the protruding rebar, or poured in place around the rebar. The rebar is meant to prevent horizontal movement. Pounding it into the rubble foundation won't prevent the walls from lifting vertically, but if something cataclysmic happens to lift the weight of 12-14 inch (18-35 centimeter) thick papercrete walls, chances are that nothing would have kept the structure from lifting.

When just a few inches of rebar are visible above the courses of papercrete, it's time to lay a piece of rebar horizontally and wire it to the protruding vertical pieces. Then pound the vertical pieces down almost level with the surface of the papercrete, cover it with a layer of papercrete mortar and start laying the next courses of blocks. It's a good idea to keep the thickness of the mortar joints to a minimum whenever possible - ideally about 1/2" (1.25 centimeters). Otherwise, the thick mortar joints will shrink and your finished walls will lose a bit of height when the mortar is fully cured. This is a good reason to wait a few weeks after the walls are up (longer in damp climates) before installing windows and doors. If the mortar joints are thick enough to allow excessive settling, windows may be broken and doors may not open very well. Usually, excessively thick mortar joints occur because not enough attention was paid to keeping the blocks level, square and true as the walls were built - the lazy way to make height and alignment adjustments. Some of this is unavoidable and not very important, but building the entire height of a wall with 2"-3" (5-7 centimeter) mortar joints will result in some settling. Using a mortar mix rich in Portland cement will minimize shrinkage and encase each block in a fireproof "container."

|

| Horizontal rebar is tied to vertical rebar for additional strength. |

But let's get back to installing the rebar. After laying up another two feet (61 centimeters) of blocks, pound more four-foot (122 centimeters) rebar through the block layers on top into the block layers below. Repeat the process above, laying a piece of rebar horizontally and wiring it to the protruding vertical pieces. If you're using slip forms instead of blocks, you can wire the horizontal and vertical pieces of rebar together, starting at the stem wall, and pour papercrete around and through them all the way to the top of the wall. This pins the entire wall together and provides a great deal of lateral strength.

There are two ways to plan for openings in the wall - either frame as you go or leave the rebar out and cut openings to size with a chain saw at a later time. If you have all of your windows and doors, or know the size of the openings, you can build frames for them as you put up the wall.

|

| Openings can be framed out for doors and windows as walls are built or they can be cut out with a chainsaw later. |

If your walls are load bearing, the frames should be substantial in case the finished walls settle slightly at the mortar joints. Do not install flimsy pre-hung doors or unframed glass as you go in load bearing walls. The settling that occurs is usually slight, but could be enough to break unframed glass or knock door jams out of alignment. If you don't know exactly what your opening sizes will be, leave the rebar out of the places where openings in the wall are planned. You can cut them to size later with a chainsaw. There is one caveat here. If you are using sand or other solids in your mix, or if you are using more cement to paper than a 50-50 ratio by weight, you may have great difficulty trying to cut openings in the walls after they are dried. Conventional chain saw blades do not cut through sand or hardened cement very well at all.

When you have reached roof height, you have a decision to make. You can attach a wooden plate to the top of the wall and build a conventional roof framework from there, or you can use vigas. Vigas are smaller-diameter logs used as roof beams. Some builders drill a hole in the vigas and anchor them to the wall by pounding a long piece of rebar into the papercrete and bending it over the viga. If you want to distribute the weight carried by the viga over a greater area, you can notch it with a chainsaw and position the flat area on the wooden plate attached to the top of the wall.

|

| A post driver is used to start the rebar, a mall is used to drive it in the last few inches. |

The wooden plate can be attached to the wall in several ways - either by 3/8” or ½” rebar, or by spot welding short pieces of threaded rods on one end of short pieces of rebar. If the rebar is used by itself, without the threaded rod, drill a hole in the plate and pound rebar into the papercrete as far as possible, hopefully a minimum of two feet. It's much easier to use a post driver than a mall or sledgehammer to do this. Allow 4"- 6" (10-15 centimeters) of the rebar to protrude from the hole and bend it over flat with a hand mall. This should be done every three-four feet depending on what is beneath the spot where the rebar is being placed. Sometimes obstructions below where the rebar is being driven, like window openings, can be avoided by driving the rebar in at an angle. Bending with a hand mall tends to enlarge the hole made by the rebar and move the block out of position, so the preferred method is using the threaded rod.

Weld a four inch piece of threaded rod on one end of as many pieces of rebar as you need to hold the roof down. In essence, you make very long bolts. Drill a hole in the wooden plate, and drive the rebar into the papercrete until an inch or so of the threaded rod protrudes above the wooden plate. Place a flat washer over the threaded rod and tighten down a nut. Do this every 3' - 4' feet along the wall. The wooden plate chosen to distribute the roof weight on the wall should be narrower than the wall - perhaps a 2x10 - so that papercrete can cover it outside and inside.

|

| The wooden plate for the roof is fastened to the wall with threaded rod welded to rebar. The rebar protruding vertically is driven through holes in the plate next to the holes with the threaded rebar. The vertical rebar will hold block in place, which is laid above the roof line. |

In my experience, adding a little Plaster of Paris to papercrete mix causes papercrete to adhere solidly to wood. The rebar method of attaching the roof framework to the wall has been used in structures in Colorado and New Mexico, which have successfully withstood weathering and storms for a number of years.

After the roof framework has been installed, you have to decide whether you want to build a conventional roof, a papercrete roof or a hybrid papercrete-conventional roof. A conventional roof is quite expensive; it averages about forty percent of the cost of the entire structure. A conventional roof has to be well insulated, or the insulating value of building the walls with papercrete will be wasted. Conventional roof systems are much more expensive than papercrete. According to one practitioner, a six-inch thick papercrete roof can be constructed for about 75 cents per square foot, including a paint sealer. A Spanish tile roof would cost $11.00 per square foot.

If you choose a papercrete roof, you have to decide whether you want to make papercrete roof panels or pour the roof. Pouring the roof is not practical if there is no water on the building site and it can't be trucked in. In that case, roof panels can be made elsewhere and brought in with a pickup or utility trailer. When making roof panels, it's best to carefully level the ground where the panels will be made so the thickness of the panels is consistent. Papercrete panels are made with 2' x 4' (61 x 122 centimeter) forms. The 2' x 4' forms should be built of 2 inch by 4inch (5 x 10 centimeter) lumber. If you make larger, thicker panels, they will take longer to dry and you may need help to get them up on the roof. To keep the papercrete clean and help drain out the water, put a sheet of shade cloth on the ground under the form. Some people use more cement in the mix for roof panels. Adding too much cement will negatively affect R-value. Strong panels are made by filling the form up to within a half-inch from the top and then spreading a piece of chicken wire over the mix. Pour the remaining half inch of mix, smooth out the surface with a trowel, and let it set. In the desert Southwest, you can pull off the form in about half an hour. You should be able to handle the panel in about four days. It will probably take the panel two weeks or so to completely dry. When the panel is placed on the rafters or vigas, the side of the panel with the wire closest to the surface should be placed against the rafter or viga. Panels made like this should require no additonal reinforcement when fastened to rafters of vigas spaced 16 inches (40 centimeters) apart. Panels layed over vigas or rafters spaced 24 inches (60 centimeters) apart may require additional support such as a layer of chicken wire stretched over the vigas or rafters before installing the roof panels.

|

| Offset chicken wire and thin layers of papercrete are installed before the roof panel. |

|

| Apply a second thin coat of papercrete to stick the roof panels in place and then screw them to the ceiling joists or vigas. |

For the greatest strength, roof panels are installed over offset chicken wire and two thin layers of papercrete. First a sheet of one-inch chicken wire is tightly stretched over the ceiling joists or vigas of the structure and fastened in place with heavy-duty metal staples. A second layer of one-inch chicken wire is offset 1/2 inch from the first and installed the same way. Then a thin layer of papercrete is spread on the chicken wire and allowed to dry to form a strong base for the roof panel.

Just before installing the roof panels, another thin layer of papercrete is spread over the base layer to mortar the panels in place. Then they are screwed to the roof joists or vigas. Since papercrete is relatively soft, the screws don't have to be as long as the papercrete is thick. They easily countersink into the papercrete as they bore into the underlying joist or viga. Once the first layer of panels are in place, you can mortar and screw on additional layers of panels or pour a layer of papercrete. If the roof is relatively flat, pouring is no problem. If greater than a 4/12 pitch, it would probably be better to mortar on a second layer of panels.

After the second layer of panels are added, a thin layer of papercrete should be added over the outside surface to fill the cracks and smooth out the entire roof surface. At this point, you can choose to leave the papercrete untreated, waterproof it, or adopt a hybrid approach - cover it with insulating foam or steel sheeting.

|

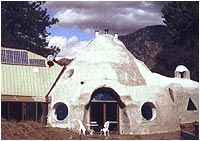

| This seven year old home is covered with papercrete

with no waterproofing. It hasn’t leaked. |

|

| A papercrete roof with surface cracks and separations, but no leaks. |

Kelly Hart has lived in a sand bag home covered with untreated papercrete for several years with no leaks. His home is located in an area where there is snow, and accompanying freeze-thaw cycles. The roof structure on his home has a fairly steep pitch, like a cone, but he says rainwater does not drain off; it sinks in before it can reach the ground - and then evaporates.

I have also visited a location in New Mexico and walked on the nearly flat untreated papercrete roof of a shed several years old. The papercrete had cracked and separated on the surface a bit, but there was no evidence of leakage.

Some people write that it is possible to waterproof papercrete with elastomeric paint like Kool Seal or Henry's products. Elastomerics are quite expensive. I've examined these products and they produce a thin, flexible rubber-like membrane when dry. When I peeled a small sheet of it off a container and tugged on the edges, it didn't stretch very much before holes started to form in it. I think it would seal the roof if it stayed absolutely intact, but no one knows for sure how long this membrane will remain flexible and undamaged under the ultra violet beating of the sun - or in cyclic freeze-thaw situations. Even roofing tar hardens and ultimately cracks in the sun. A papercrete roof is slightly springy; it has a little "give" in it. I would worry about walking on it and stretching the elastomeric membrane. If it cracked or perforated at all, and water were trapped under it, mold, mildew, fungus or degradation in the papercrete could follow. One practitioner is extremely concerned about mold. He feels that using a solid papercrete roof is risky "except when another kind of material (such as a metal roof) is assembled over it, and the papercrete can breath to allow any possible leaks to air out. This appoach is also much more healthy for the inhabitants of the structure, since breathability

has been established as desirable for a "healthy" house.

Two other practitioners I spoke with said that elastomeric paint has a good record when used per instructions. Applying elastomeric paint is a two-step process. If the primer and finishing coat are used as recommended, it gets high marks they felt. Both also recommended crystalline waterproofing.

|

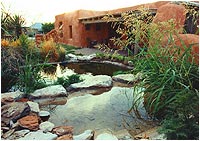

| A pond made of papercrete sealed with crystalline waterproofing. |

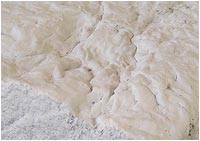

Long available for industrial applications, crystalline waterproofing is now used in residential applications. It consists of a dry powder compound of Portland cement, very fine treated silica sand, and proprietary chemicals. Combining the product with water and applying it to the surface of concrete results in a catalytic reaction that forms several inches of non-soluble crystalline fibers within the pores and capillary tracts of concrete. This seals the concrete against the penetration of water or liquids from all directions. UGL DryLok is one of these products. Supposedly this will work in either cured papercrete or in the wet mix itself. It's pricey, but said to be so effective that it’s possible to make ponds with papercrete. If it will hold water without leaking, it should prevent water penetration.

Coating the outside of a papercrete roof with about an inch of Sprayed Polyurethane Foam (SPF) is another approach. It is expensive, and not environmentally sensitive, but it may be a good compromise. I walked on this kind of roof in Prescott, Arizona, where the sun is very strong, and there were no problems with it. It's tough, flexible and absolutely waterproof. With reasonable caution, it can be walked on without worrying about puncturing it, though it is vulnerable to heavy pointed objects. It also adds an additional R 6.88 per inch of insulation to the roof. That is the equivalent of another three inches of papercrete. Add that R-value to two four-inch thick papercrete roof panels with mortar, and the total R value is about the same as the walls. That is a great envelope for a home, especially considering that the roof would weigh about eleven pounds per square foot. At that weight, if a wall were supporting a 25 foot (7.6 meter) span of roof by itself (unlikely), the total load at the base of the wall would be about 550 pounds per square foot. That is a little less than four pounds per square inch. Since papercrete is variously rated at well above 100 pounds per square inch, there is a very wide margin for wet snow or any other additional roof load.

|

| This five year old papercrete workshop has a poured roof covered with steel roofing. |

Another approach to roofing in New Mexico was poured papercrete with a metal roof installed over it. This hasn't leaked since the building was built five years ago.

Some people prefer to place wet papercrete directly on the roof rather than go through the process of making, cutting and fitting roof panels. This works fine for structures with nearly flat roofs. Of course, a nearby source of water is required.

|

| Inside a shed with a poured roof. Two layers of offset chicken wire hold the slurry while it dries. | A layer of one-inch chicken wire is tightly stretched over the ceiling joists or vigas of the structure and fastened in place with heavy-duty metal staples. A second layer of one-inch chicken wire is offset 1/2 inch from the first and installed the same way. Ideally, the papercrete is drained on the ground and then pumped, augured or handed up to the roof in buckets. Mike McCain has used a four-inch grain augur to lift papercrete to roof heights. A number of people have written that pumps are not reliable, but others have found ways to make them work.

A few inches of papercrete are spread over the chicken wire, which sags somewhat under the weight. After it is allowed to dry, a second layer of papercrete - and possibly additional layers - are placed the same way. The unintended advantage to this method is that the papercrete sags down between the ceiling joists or vigas thereby providing greater thickness and more insulation value. The down side is that wet material is heavy to work with. Of course, cutting papercrete panels is dusty, so it all depends on which method you like best.

|

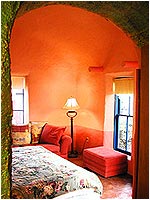

| A bedroom with vaulted ceiling of papercrete. | After the roof is poured and smoothed out, the same waterproofing methods can be used as those for roof panels described above. Another way to go is to build a vaulted roof or domed roof out of blocks right on top of the walls. See

Domes. This method has been done successfully, with beautiful results, in Texas by Clyde T. Curry. Besides saving the cost of the roofing framework, the domed or vaulted ceilings of papercrete provide good insulation.

If windows and door are pre-hung in their own frames, they can simply be screwed into the papercrete opening. The gaps can be trimmed conventionally and/or filled with papercrete. I have had success adding a small amount of Plaster of Paris to papercrete where it comes into contact with wood. Mixed this way, the papercrete adheres very firmly to the wood. Before drywall, which is Plaster of Paris between sheets of paper backing, wood lath was nailed to studs and covered with plaster to finish walls. That might explain why the papercrete/plaster mix works so well with wood.

|

| Short wall sections between windows were screwed to window frames for added stability. |

|

| Frameless glass can be embedded in papercrete without fear of cracking. Outside bottom is not covered to allow drainage. | If wood or metal frames have to be installed, they can be screwed directly into the papercrete. The opposite is also true. At a construction site in New Mexico, I saw narrow sections of unsupported papercrete block walls, between floor-to-ceiling windows, angle-screwed to the window frames. The frames themselves were independently anchored to the floor and to the roof plate. This stabilized the short walls extremely well. Any gaps are filled with papercrete and the inside surface of the wall opening (not covered by the frame) can be surfaced with papercrete.

Papercrete has another quality, which makes it ideal for installing frameless glass. The glass can simply be embedded in the papercrete. Papercrete doesn't expand or contract perceptibly, even when wet or frozen, so sheets of glass or glass block can be embedded in and trimmed with papercrete without fearing that they will be damaged by expansion or contraction of the papercrete.

Windows and doors should ideally be insulated or the R-value benefit of papercrete walls and roof is compromised. Windows should be at least double paned, but that costs more. It is easier to find cheaper, older single-pane windows and unframed glass than newer multi-paned windows. The older windows have character and look more substantial. Since glass can be embedded in papercrete, so can several separate sheets of glass or two complete windows. The one on the inside should be open-able for cleaning. The air between the panes is the best possible insulator, so if using two single-pane windows, space them as far apart as is convenient. In extreme climates, insulated doors or two-door entryways should be built to minimize heating and cooling loss.

|

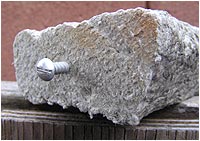

| Screws are the anchor of choice for papercrete. | China cabinets, pre-built shelves, medicine cabinets and anything else, which has to be anchored to the wall can be firmly anchored with screws. Papercrete does not hold nails any better than drywall, but screws work very well and will hold a considerable weight. The great thing about screwing into a papercrete wall is that you don’t have to look for a stud. You can anchor any object exactly where you want it.

Installing plumbing lines requires cutting holes and channels in papercrete. This is fairly easy if original papercrete mix didn't have a surplus of solids (sand, powdered glass) or cement in it. Cutting papercrete results in a lot of dust. Consider wearing a mask or respirator. Holes and channels can be made with conventional drills and a chainsaw. Once the pipes are soldered and pressed into slots in the papercrete, they are covered with more papercrete. The benefit is that the entire plumbing system is insulated. Cold stays cold and hot stays hot longer - less wasted energy.

Narrow channels for electrical runs can be cut with a circular saw or chain saw. To make holes for outlets, cut horizontal and vertical slits with a circular saw. Then pry out the unwanted piece with a screwdriver. One of our practitioners mentioned that he puts a glob of non-flammable mortar behind his outlet boxes for safety, since most home fires start where the wiring enters the outlet boxes. Outlet boxes can be angle-screwed directly into the papercrete. Once the electrical wiring and outlets are installed and tested, the channels for the electrical runs are filled with papercrete.

|

| Papercrete stucco sticks to concrete block very well. The lighter sample on the left was mixed 50-50 by weight with Plaster of Paris - the one on the right with 60-40 Portland cement. |

|

| One coat of inexpensive latex paint without a primer covered this papercrete sample very well. | Exterior finish can be papercrete, stucco or a 60-40 mix of papercrete/stucco. Some practitioners use two sacks of Portland cement and make their stucco the same way as their blocks. Doubling the amount of Portland cement in the papercrete gives it more strength and resistance to abrasion. One practitioner we spoke with uses six sacks of Portland cement and paper- no sand or other components - to make wall plasters. He feels this is essentially what is being purchased when buying exterior stucco. Papercrete stucco can be painted with exterior latex paint. I examined a small home painted this way. The paint had been in place for over three years and looked like it had been recently painted. Papercrete stucco takes paint very well. Without a primer, one coat covers quite well. For peace of mind, two or three coats are advised. Rather than pay the high cost of a primer or multiple coats of the same color paint, just purchase latex paint that has been color-matched incorrectly or abandoned at the paint counter. Most stores will sell it for about four dollars a gallon. It is perfectly good paint, just not the right color. All the different "mistakes" can be mixed together and used for the first coat or two. Then apply the color you want as the final coat.

|

| Foam and acrylic-based stucco over papercrete. |

|

| Five year old El Rey stucco over papercrete. | Stucco adheres to papercrete walls very well with or without the use of stucco mesh. Andy Hopkins' house in Colorado has a textured stucco coating, which feels like hard plastic. Andy has sold the house so the type of stucco couldn't be determined. It was some kind of new foam and acrylic-based stucco. This type of stucco stuck to the papercrete very firmly, looked great and was weathering fine.

Classic El Rey stucco was used on a shed visited in northern New Mexico. This type of stucco is made with Portland cement, and is colored all the way through - so a scratch or nick won't be easily seen. The shed was five years old and the stucco was in nearly perfect condition.

Classic stuccoes and a number of new acrylic formulations are available in many colors and textures. Some are quite expensive and some require an environmental premium. Keep in mind that papercrete stucco looks great and can wait until a better solution becomes available. Lime might be considered as well.

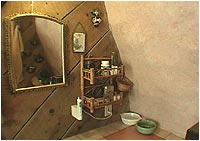

Interior finishes include many of the same alternatives as exterior. One approach to interior finish was used in a large home in Arizona. The owner covered all interior surfaces with a thin layer of drywall joint compound. A few cracks developed over time.

Kelly Hart has used a white lime wash, which is particularly attractive, in several rooms of his home. He also discovered a way to mix latex paint 1:10 with water to produce beautiful water-based stains. His bathroom stain is particularly attractive. Stains not only dress up the look of the papercrete, they also cut the cost and amount of paint used by ninety percent!

|

|

| Lime wash on papercrete ceiling. |

A stained papercrete wall in a bathroom. |

Many people using papercrete prefer alternatives to concrete floors, because of expense and environmental issues. Papercrete itself may not be the best solution for floors since the point pressure of table and chair legs will indent it - unless a great deal of cement is used. One practitioner we spoke with makes papercrete floors in yard quantities, about 200 gallons, with six sacks of Portland cement and about 45 shovelfuls of sand. That provides a hard enough slab to work well with floors.

Some people use papercrete as a sub floor to insulate the floor from the surrounding earth and provide a base for a radiant heating system.

|

| An adobe earth floor inlaid with flagstone. |

An earth floor made of adobe, or adobe mixed with papercrete instead of straw, is an alternative. Earth floors can be finished and decorated in various ways. There are many books available about building earth floors.

Another lesser-known option for floors is tamped road base. Road base, sometimes called "city base," is what is used for making roads. Be careful. If you simply ask for " road base", you may get common ABC gravel with little else in it. The type of road base you need has a mix of rock, sand, clay and dirt in specified quantities approved by cities for roadbeds. In the Phoenix area, the material is called ABC MAG. The MAG stands for Maricopa Association of Governments. This is a consortium of cities in Maricopa County where Phoenix is located, hence "city base." ABC MAG has a mix of under one-inch rock, sand, clay and dirt. This material is applied in several layers. Each layer is screened finer, dampened, screed, tamped and troweled smooth. After finishing, the top layer should be as smooth and level as a conventional floor.

Successive screening is a lot of work. With some investigation it's possible to find out what the constituents of the road base are. Buy them separately and dry mix them using aggregate sizes appropriate for each layer. This saves a good deal of labor.

The finished floor is sealed with boiled linseed oil and turpentine. The entire process is described in a chapter called "A Tamped Road Base Floor" in "The Art of Natural Building."

Road base can only be had in the colors of nature and the colors vary from location to location. In the Phoenix area they vary from gray to brown. In Austin, I'm told they are reddish. There are probably ways to vary the color. An advantage to road base is drying time (which is much faster than adobe.) It only takes a few days in dry climates.

Road base costs under $5.00 a ton, if you pick it up. Working with it is easy - no mixing straw, clay, papercrete, etc. Two 12-ton truckloads cover 500 square feet. It is also very durable having a plasticity index (in Phoenix) of 0-5. The plasticity index is a measure of a materials' tendency to sag. Smaller numbers are better, but it's common to see ratings of up to 12.

This is where papercrete shines. With a papercrete envelope and well-insulated doors and windows, much smaller heating and cooling systems are possible.

In fact, with some planning, the heating system of the home can be built into the floor. Solar heated water is circulated though a serpentine system of plastic pipes embedded in the floor to produce radiant heating. Since the floor has quite a bit of mass, the heat is retained for long periods when the water isn't being heated, such as at night. Usually a small fireplace or electric heater can easily supplement the radiant heating.

Cooling costs are also greatly reduced. A much smaller air conditioner or evaporative cooler can be used. If you want to live comfortably off-grid, newer solar power systems are an option. The new high-tech systems are computer-integrated with wind-power generators and propane generators. On extremely hot or cold days, when quick heat or cooling is necessary, the new systems seamlessly move to the generator. As soon as the demand falls within the supply parameters of the solar or wind equipment, the system switches back to them. So fossil fuels are only consumed when peak demand requires. This kind of system is also modular. The initial system can be small if you are living in part of a structure while building the rest. As you add on to the structure, additional modules can be added to provide the increased capability you need. This is great because you don't have to buy more capability than you need before you need it.

|