|

Anecdotally, a lot is known about papercrete, but not much has been formally tested. We will be testing as many parameters as time and funding permits. As results become available, they will be posted at the end of this section. In order to gain visibility and acceptance in the marketplace, a battery of tests will have to be run, standards set and quality controls initiated. Some of the tests which need to be run, after a standard mix is established, are as follows:

Material Characterization - Compressive strength, tensile strength, shear strength, long term deformation (creep), water permeability, fire resistance, heat and sound insulation, long term behavior (degradation).

Structural Elements - Strength in pure bending, strength in axial force and bending moment, strength in shear, effect of reinforcement.

Although we may not be able to accomplish all of this testing in the near future, these are the types of tests which will be required over time to provide architects and design engineers the information they need to establish papercrete as a mainstream building material.

|

We have tested more than 50 different combinations of materials. We are looking at various percentages of Portland cement, Portland and sand, Portland and fly ash, Portland and rice hull ash, clay, Styrofoam, lime and paper mill sludge.

We first look at compressive strength. Then we examine thermal properties, creep and pull tests. We

have also investigated cure time by testing identical samples over time.

Blocks made adobe style vary from blocks made in a press. Pressed blocks are

much stronger, more regular and water efficient. |

| Test samples drying on shade cloth. |

New TECHNICAL REPORT now available. |

The basic constituents of the test mixes are:

1. Paper/Portland Cement

2. Paper/Portland/Sand

3. Paper/Portland/Fly Ash

4. Paper/Portland/Rice Hull Ash

5. Paper/Portland/Styrofoam

6. Paper Mill Sludge/Portland./Fly Ash

7. Paper/Portland/Glass

8. Paper/Portland/Clay

9. Paper/Portland/Lime

*10. Hammermilled paper

After initial tests on these mixes, we will narrow down the alternatives and try cross-over mixes based on which initial mixes test best. For example if, the Paper/Portland/Styrofoam combination has a superior compressive strength, we may want to try Fly Ash as a substitute for a percentage of the Portland cement to see if we can reduce the costs of the mix. Other tests involving ground low-grade paper and cardboard are also planned.

We recently sent a sizable sample of junk mail, paper packaging, and other paper collected around the house to Schutte Hammermill in Buffalo, New York. They are helping us research the proper hammermill and screen size to use for "hammering" low-grade mixed paper into a dry fibrous mass, which can be more easily handled and mixed than un-milled paper. Using "hammered" paper would allow mixing in a conventional rolling mixer or even a cement truck with a rolling mixer.

Specifications for papercrete do not yet appear in ASTM and extensive engineering tests have not yet been run on papercrete. We have begun contacting officials in the ASTM organziation and the ICC to determine a procedure for seeking approval of one or more of the mixes we are testing. More testing needs to be done in recognized and controlled engineering environments. That having been said, there are a growing number of homes and other structures built of papercrete (some of which have been standing for many years) so there is little doubt that papercrete works well as a construction material.

The compressive strength of papercrete has been measured a number of times and is variously reported to be in the 140-160 lb./sq. inch range -- but compressive strength is probably not the most accurate way to judge papercrete. Compressive strength is a measure of load at the instant of failure. This works for concrete because when concrete's load is exceeded, it literally explodes. When that point is reached, the compressive strength is known. But papercrete never fails catastrophically, it just compresses like squeezing rubber. So a more accurate measure of papercrete's strength is its stiffness - in other words, how much does it compress under what load? We have found that this value is less than the compressive strength of concrete, but many times greater than would be needed to support any kind of roof combined with just about any roof load. So with papercrete, you don't have the sudden catastrophic fragmentation, which is characteristic of concrete or earth, just a slower squish. When the load is removed, papercrete actually rebounds a bit in an attempt to return to its prior shape. What does this all really mean? It means that papercrete has no problem with strength. A structure several stories high can be built with it. The next issue is creep. What will happen to a papercrete wall under constant load over time? Will it slowly compress or will it keep its shape?

The tensile strength of papercrete also seems sufficient to the task. Just try to pull a single sheet of paper apart by pulling laterally on the edges. It has great strength. Ripping a piece of paper is much easier than pulling it apart. So the shear strength of paper is not as great as its tensile strength. But a papercrete block is the equivalent of hundred of pages of paper - almost like a catalog. Papercrete has very good sheer strength as a block. Lateral load involves sideways force - the wind load on the entire area of an outside wall for example. Because papercrete walls are usually a minimum of twelve inches thick, and usually pinned with rebar, they are very strong laterally. No extremely long lengths of flat wall built with any kind of material should lack reinforcement. The reinforcement might be internal - using mesh or rebar, or external by curving the wall or connecting the wall to perpendicular walls at reasonable intervals. Structural testing will tell us the best way to design for papercrete construction. Again, papercrete is not yet part of the Universal Building Code, but in practice works very well.

"R-value" is a measure of a material's resistance to heat flow. The R-value of papercrete is reported to be between 2.0 and 3.0 per inch - the higher the number, the better. I have seen documentation from the Department of Energy, which was done on two samples of Lex Terry's blocks. Lex uses a 1:1 mix of Portland cement with Fly ash to paper, with about 12 shallow shovelfuls of sand added. His two samples came back from DOE with R-values of 2.24 and 2.16. The percentage of Portland cement and fly ash was 65% Portland cement and 35% fly ash. Lex makes his blocks 12 inches (30 centimeters) thick. He adds an average of about an inch (2.5 centimeters) of papercrete exterior stucco and about the same amount for interior finish. That means that his total R-value will be at between 30.24 (14 x 2.16) and 31.36 (14 x 2.24). That's quite good compared to an older standard wood frame wall of R- value 19. The R-value of hollow masonry block is only 1.75.

Fire -

There have been several reported incidents

involving papercrete and fire. One of them was a case of arson. A gallon can of

gasoline without its top was thrown on the roof of a papercrete shed – followed

by a lighter. The accelerant eventually caused the papercrete to begin

smoldering like charcoal. A volunteer fire group responded and had to return

several times before they understood that papercrete smolders and does not burn

with an open flame - they thought the fire was out. When they thoroughly doused

the smoldering area with water and scraped out the blackened material, they put

it out. Firemen in larger cities routinely do this when putting out fires in

blown-in attic insulation, which is similar to the pulped paper in papercrete.

Another fire was caused by

a plumber, while sweating on copper water-line connectors with a torch.

Apparently he didn’t use something to shield the paper blocks from the torch.

No one noticed that a block had started to smolder. When someone did notice, 36

hours had passed. The blocks in a four-foot square section of wall had been

reduced to ashes.

While the issue of fire

should never be minimized, I think a wider perspective is helpful. In my area

of the country, several construction fires caused by grinders, torches or

welders make the evening television news each year. There are numerous other

fires, which are contained by workers themselves and don’t get broadcast. In

some cases, these fires result in spectacular losses, which occur in less than

20 minutes – and once in a while people get hurt or killed. When these things

happen there is never a suggestion that wood should be outlawed for construction

purposes.

My point is this. I would

rather live in a structure, which would give me hours and hours to locate and

fight the fire than in one, which would incinerate me before I can get to the

front door.

Having said that, caution

is always the best policy. Watch what you’re doing with anything that gets hot

or produces sparks or flames around this material, or wood, or fabric or

anything else that might burn. I once pounded a piece of rebar into a

papercrete wall, which veered off vertical and came out through the wall right

where I wanted to locate a door jam. I didn’t want to go through the trouble of

extracting the rebar so I decided to cut it back from the door jam by slicing

into the block with a grinder. I knew there was a fire risk so I had a bucket of

water nearby. I sliced into the block with the grinder and cut off the rebar in

a hail of sparks that lasted several minutes. I thought I would surely set the

block on fire, but it didn’t burn. I stuck my pinky back in there when the rebar

had cooled, and watched it closely for a few hours while working in the area,

but no fire. Maybe it was because I use quite a lot of Portland, fly ash and

sand in my blocks. The more inert ingredients in something, the more difficult

it is to burn.

I think the question is

does papercrete catch on fire more easily than other materials and I really

don’t believe that it is more flammable than anything else under normal

circumstances. Anything - even rock - can be burned when the conditions are

right.

Our block and roof panel mixes cure into a material which will not burn with an open flame. If an accelerant like gasoline is applied to it or it's held over an open fire for a prolonged period ( 30 seconds or more) it will begin to burn slowly like charcoal rather than rapidly like wood.

| It will eventually be reduced to ashes, but a single block will take several hours to be consumed. However, I recently witnessed a way to treat it so that it will not burn at all. Artie Skeeter, from Blue Lake, California working with

Shane Keller from Arcata, California, tried some textile fire retardant on papercrete. Many fire retardants are expensive and give off toxic fumes, but a mixture of boric acid and borax is environmentally friendly and will protect the block from fire. Boric acid is used in eye washes. This concoction has been used for years to treat curtains, draperies and other textiles in theaters, playhouses and dance clubs where people congregate in great numbers. |

|

The National Fire Prevention Association (Reg. 701) Standard Methods of Fire Tests for Flame Propagation of Textiles and Film (1977)

provided some uncomplicated formulas. |

This paper Crete, coated with a boric solution, was held in an open flame for two minutes. |

Artie and Shane settled on 1 cup of Borax and 1 cup of Boric acid in a gallon of water. It's not too expensive and the great thing is that it seems to work. Another great thing is that it's not necessary to treat all blocks. The interior plaster and exterior stucco used with papercrete contains a high percentage of Portland cement. That in itself will not burn. So the only weak point is inside the block near electrical outlets, switches and other places where wires goes through walls, into boxes, etc. Properly wired, these places should never cause a fire, but many home fires are

|

traced back to faulty installation of wiring. So if you want to be extremely safe, we recommend soaking the outlet holes, switch box holes and anywhere wire goes through walls with the above solution before installing the boxes. This is not to say that papercrete will never burn. Any material will burn or melt if enough heat is applied - even rock. But for all practical purposes, papercrete is relatively safe (safe as or safer than wood) without being treated. It's even more safe with the boric acid solution above.

|

After two minutes in the fire, it blackened but did not catch fire,

smolder or burn. |

|

Wicking -

Much had been written about wicking - that is the capillary action of liquids (in this case water) through construction materials such as concrete. The idea is to prevent water from wicking from the ground through the footing and up the stem wall (defying gravity) into the papercrete wall - a potentially serious problem.

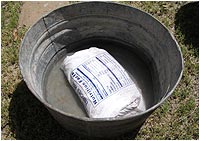

|

| A simple wick test. |

Since we mentioned using sand bags for a foundation - see

Foundations , we wanted to double check that such bags wouldn't wick. We first filled a bag with what looked like sandy soil. We placed the bag into a metal basin and filled the basin with water half the depth of the bag. Within two hours, the top of the bag was sopping wet. The water had defied gravity and climbed to the top of the bag. We were amazed that this had happened since the soil we used was quite sandy, or so it appeared. We ran a "shake test" on the soil - see

FORMULAS - Fidobe and Padobe - and found out that the soil was actually 30 percent clay. We then repeated the test above with "all purpose" sand purchased from Home Depot. We allowed the bag to sit in water over night and there was no wicking at all. It is not a secret that sand will not hold water, but we were somewhat confused by the fact that soil can appear so sandy and yet, in combination with clay, wick like a sponge. So, the lesson is if sand bags are used for the stem wall, make sure the sand is really sand. If the sand is not purchased - that is, obtained from a river bottom or other source - be sure to run a wick test as described above before using it. Since the test is so easy, it might be a good idea to test every load to make sure that other soil types are not contaminating the sand.

Glue -

|

These two pieces of papercrete were cut and ground for test purposes. Their finished dimension was 3 1/2 x 3 1/2 inches (about 9 x 9 centimeters). We wanted to find out how well conventional white glue would hold the pieces together so we put a medium amount of glue (several tablespoons) on the bottom piece, layed the top one in place and let them set over night.

The result was remarkable. They will not come apart. We have tried everything short of destroying the pieces to get them apart. |

This would seem to indicate that papercrete could be used in applications calling for quick assembly by cutting the pieces to size in advance and letting the user simply glue them together.

We will be posting the results of engineering structural tests and other informal test as they become available. |